DAF Thickener Control Enclosure

Unlocking the Power of Wastewater Treatment: Understanding DAF Thickener Systems

In the world of wastewater treatment, efficiency, and effectiveness are paramount. One of the key components in achieving these goals is the Dissolved Air Flotation (DAF) thickener system. This sophisticated technology plays a crucial role in the separation and removal of suspended solids from wastewater, making it an indispensable tool in various industries. Let's dive deep into the workings, benefits, and applications of DAF thickener systems.

What is a DAF Thickener System?

A DAF thickener system is a water treatment technology designed to remove suspended solids, oils, and other contaminants from wastewater. The process involves dissolving air in the water under pressure and then releasing the air at atmospheric pressure in a flotation tank. The released air forms tiny bubbles that adhere to the suspended particles, causing them to float to the surface, where they are removed by a skimming mechanism.

How Does It Work?

Pre-Treatment: Before entering the DAF system, the wastewater often undergoes pre-treatment to adjust pH levels and add coagulants or flocculants. This enhances the aggregation of particles, making them easier to remove.

Air Saturation: In the saturation tank, water is saturated with air under high pressure. This creates a solution where air is dissolved in the water.

Flotation Tank: The pressurized air-saturated water is released into the flotation tank at atmospheric pressure. As the pressure drops, the dissolved air comes out of solution, forming microbubbles.

Bubble Attachment: The microbubbles attach to the suspended solids, oil droplets, and other contaminants in the water. This reduces the density of these particles, causing them to float to the surface.

Skimming: A skimming mechanism removes the floating sludge from the surface of the water. The clarified water at the bottom of the tank is then discharged or further treated.

Benefits of DAF Thickener Systems

High Efficiency: DAF systems are highly effective at removing a wide range of contaminants, including suspended solids, oils, and greases, resulting in clearer and cleaner effluent.

Compact Footprint: Compared to other treatment methods, DAF systems have a relatively small footprint, making them suitable for facilities with limited space.

Versatility: DAF thickener systems can handle varying flow rates and contaminant loads, making them versatile for different industrial applications.

Improved Sludge Handling: The thickened sludge produced by DAF systems is easier to handle and dewater, reducing the overall volume and disposal costs.

Cost-Effective: By improving the efficiency of contaminant removal and reducing sludge disposal costs, DAF systems can lead to significant operational savings.

Applications of DAF Thickener Systems

DAF thickener systems are utilized across a wide range of industries due to their versatility and effectiveness. Some common applications include:

Municipal Wastewater Treatment: Enhancing the removal of suspended solids and improving the quality of effluent discharged into the environment.

Food and Beverage Industry: Removing fats, oils, and greases from wastewater generated during food processing.

Oil and Gas Industry: Treating produced water and other waste streams containing oil and suspended solids.

Pulp and Paper Industry: Clarifying process water and recovering valuable fibers from wastewater.

Textile Industry: Removing dyes, chemicals, and suspended solids from textile wastewater.

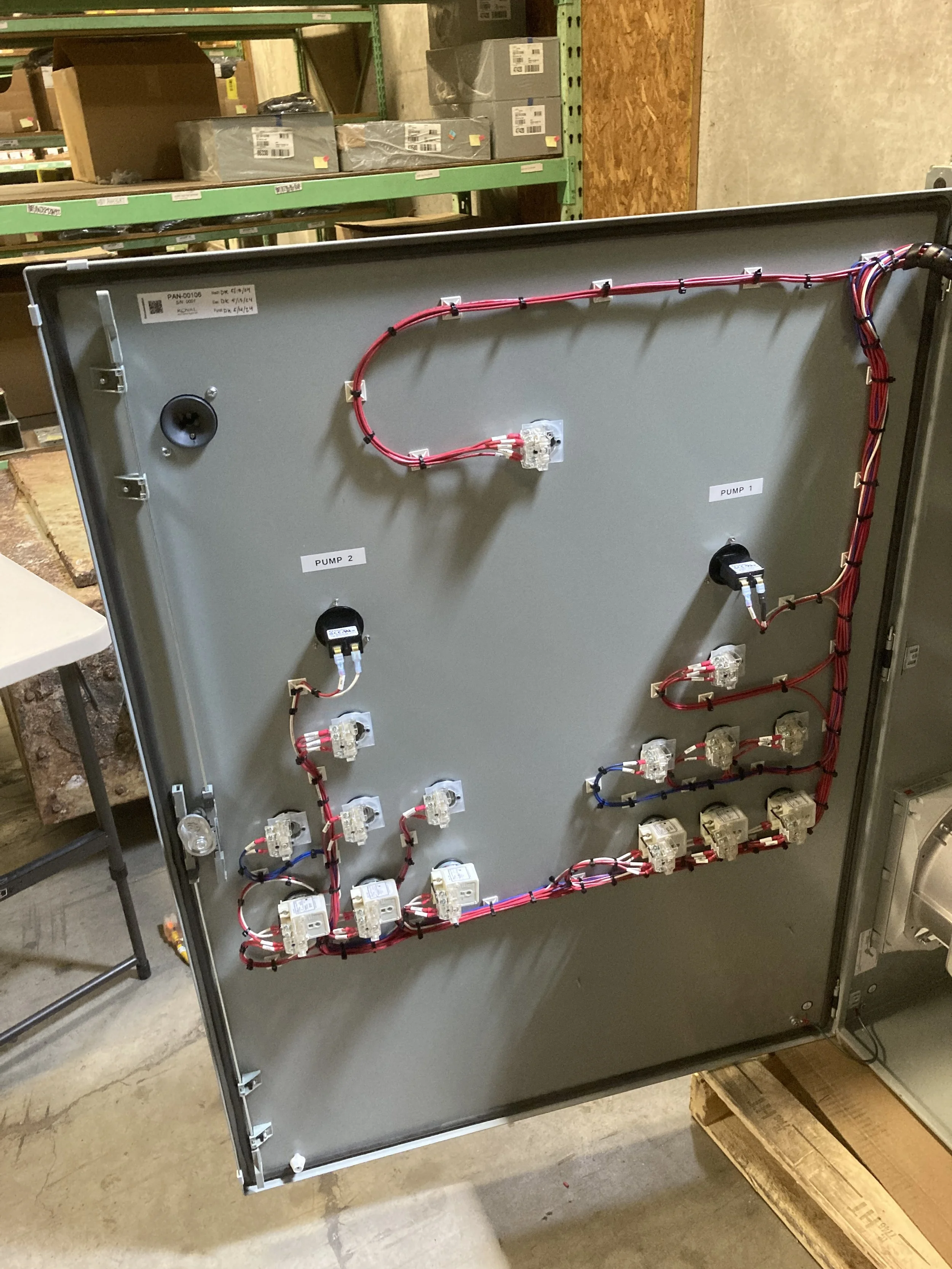

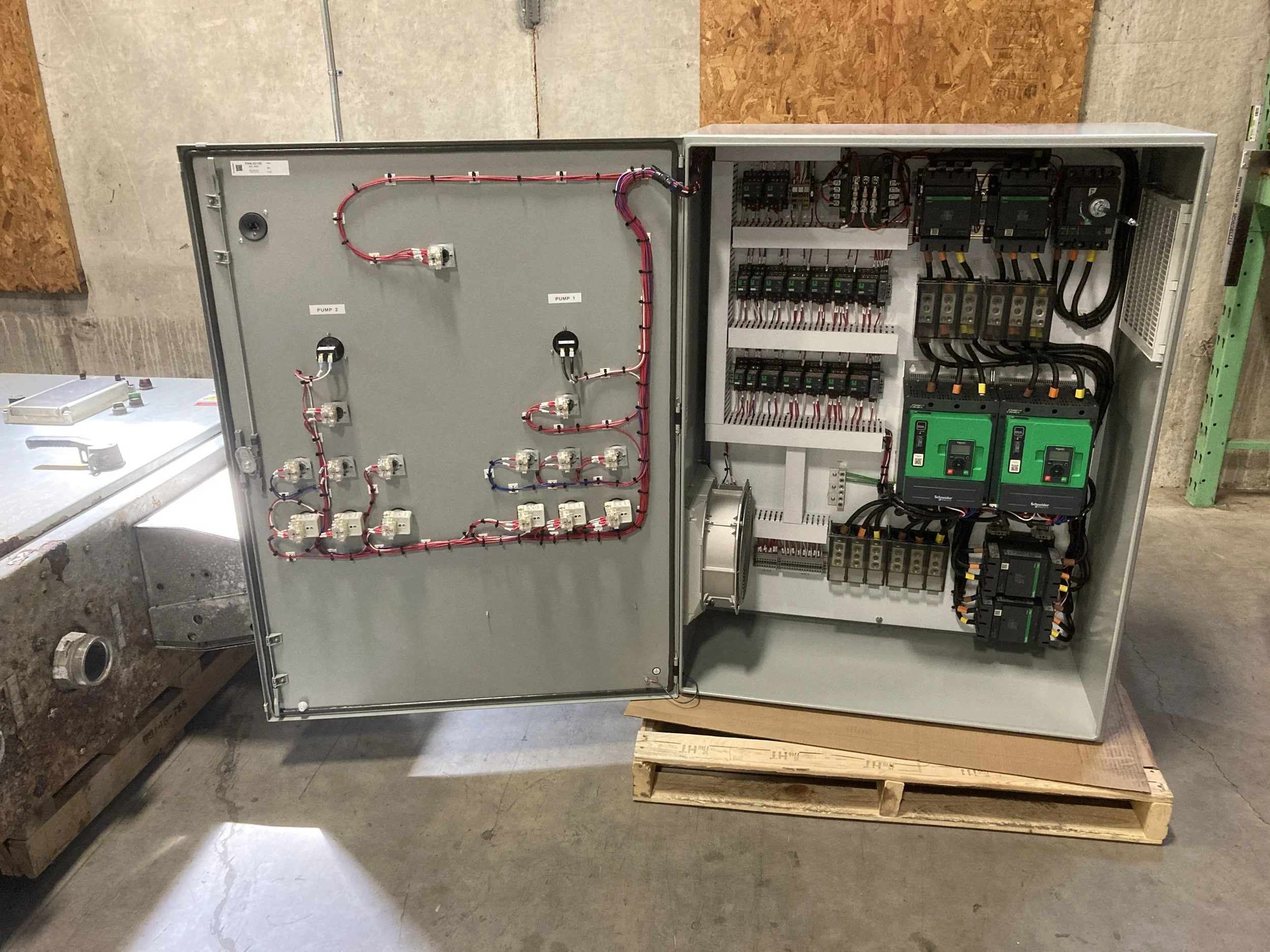

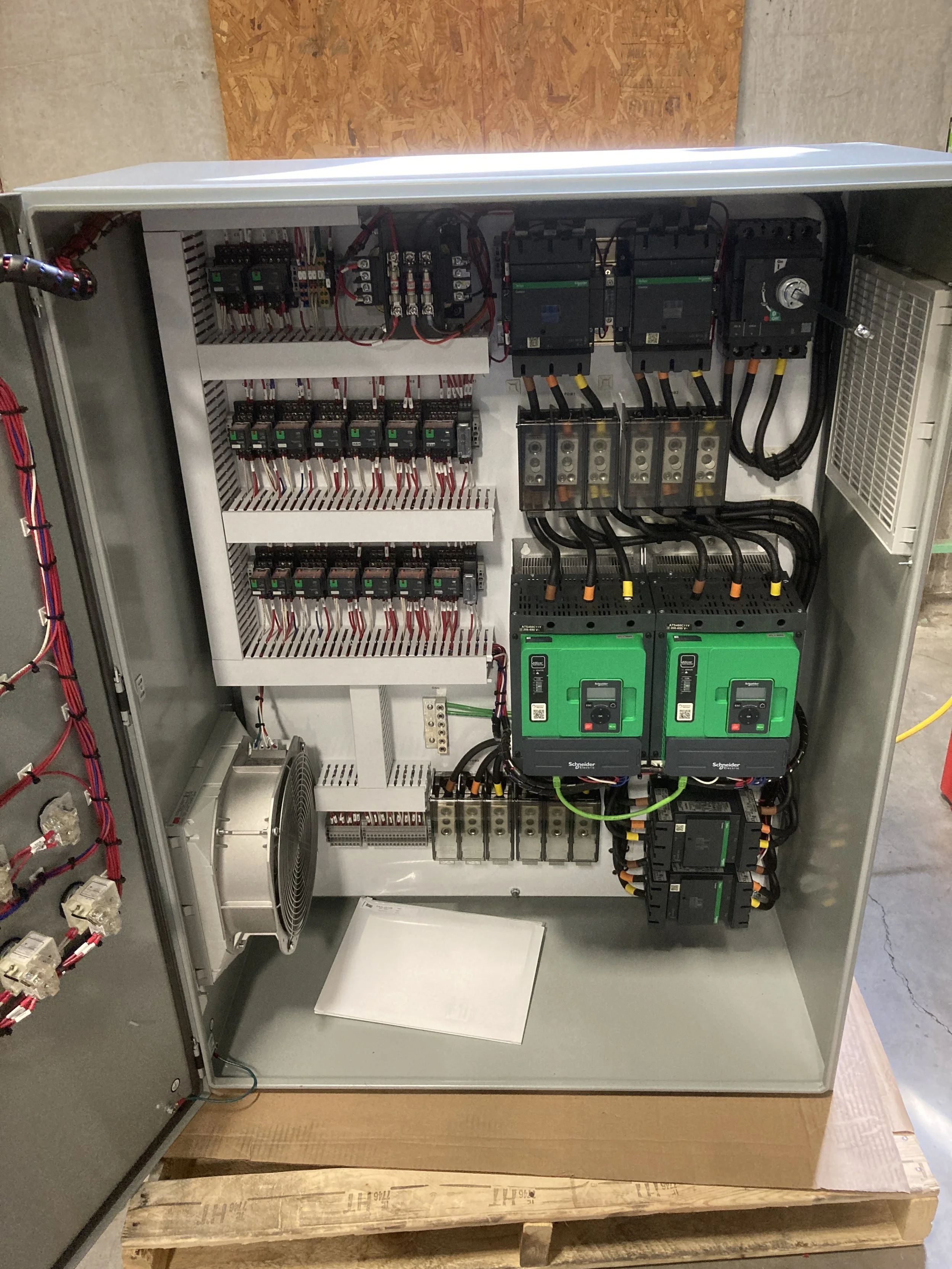

Lets Take a Look at Our System

This bespoke electrical enclosure was built and designed to operate two independent pump motors to move waste water as part of the DAF thickener. Soft starters were included to reduce in-rush voltage and alleviate stress on the pump motors. Terminal blocks and control components enable both local and remote control of the system.

Conclusion

The DAF thickener system stands as a cornerstone in the field of wastewater treatment, offering unparalleled efficiency and versatility in removing contaminants from water. By leveraging the principles of dissolved air flotation, industries can achieve cleaner effluent, reduce environmental impact, and lower operational costs. Whether in municipal treatment plants or industrial facilities, DAF systems are transforming the way we handle wastewater, paving the way for a more sustainable future.