Dual-Axis Gimbal for Remote Payload/Optics

In the fields of surveillance, reconnaissance, and advanced imaging, enabling a dynamic multi-axis field of view while maintaining stability and precision is paramount. Whether you’re working with high-powered optics for long-range observation or sophisticated positional tracking systems, even the slightest movement can significantly impact accuracy. This is where dual-axis gimbals come into play. Designed to stabilize and control equipment across two axes—typically pitch (up and down) and roll (side to side)—dual-axis gimbals are essential tools for ensuring optimal performance in both optics and positional tracking applications.

What is a Dual-Axis Gimbal?

A dual-axis gimbal is a stabilization device that enables precise control over the orientation of attached equipment, such as cameras, sensors, or tracking devices. By compensating for unwanted movements and vibrations, a dual-axis gimbal ensures that the equipment remains stable and accurately pointed, even in dynamic environments. This is crucial for applications where high precision is required, such as in optical systems used for surveillance, targeting, or scientific research, as well as in positional tracking systems that rely on exact measurements.

Applications of Dual-Axis Gimbals in Optics

Surveillance and Reconnaissance: In military, law enforcement, and security operations, optical systems mounted on dual-axis gimbals provide stabilized imagery, allowing operators to maintain a clear view of targets or areas of interest. This is especially important for long-range observation, where even minor movements can cause significant image distortion.

Scientific Research: High-powered telescopes and microscopes often require extremely stable platforms to achieve clear, accurate images. Dual-axis gimbals help in maintaining the precise orientation of these instruments, enabling researchers to conduct detailed observations and measurements.

Aerial and Maritime Observation: Cameras mounted on drones or ships can capture high-quality imagery despite the movement of the vehicle or vessel. A dual-axis gimbal stabilizes the optics, allowing for smooth, jitter-free video or still images, which are essential for tasks like environmental monitoring, mapping, and search and rescue operations.

Photography and Cinematography: For professional photographers and filmmakers, dual-axis gimbals provide the stability needed to capture sharp images and smooth video, even in challenging conditions. This technology is particularly useful for handheld or drone-mounted cameras.

Applications of Dual-Axis Gimbals in Positional Tracking

GPS and Navigation Systems: In advanced navigation systems, precise positional tracking is critical. Dual-axis gimbals ensure that GPS antennas or other tracking devices maintain their correct orientation, leading to more accurate location data. This is particularly important in applications like autonomous vehicles, where precise navigation is essential.

Robotics: In robotic systems, especially those used in manufacturing or medical fields, positional accuracy is vital. Dual-axis gimbals allow robots to maintain steady positions or follow precise paths, improving the accuracy and efficiency of tasks such as assembly, inspection, or surgery.

Target Tracking: In both military and civilian contexts, dual-axis gimbals are used to stabilize and control targeting systems. Whether tracking moving objects or maintaining a fixed position on a specific point, gimbals ensure that the tracking system remains locked onto its target, despite any external disturbances.

Virtual Reality (VR) and Augmented Reality (AR): In VR and AR applications, accurate positional tracking is essential for creating immersive experiences. Dual-axis gimbals help maintain the precise orientation of sensors or cameras, ensuring that virtual elements align correctly with the real world.

Benefits of Using Dual-Axis Gimbals in Optics and Positional Tracking

Enhanced Stability: The primary advantage of dual-axis gimbals is their ability to stabilize equipment, reducing the impact of vibrations and unintentional movements. This is crucial for maintaining image clarity and tracking accuracy.

Improved Precision: By controlling and adjusting the orientation of optics and tracking devices in real time, dual-axis gimbals ensure that these systems operate with the highest possible precision.

Versatility: Dual-axis gimbals are highly adaptable and can be used with a wide range of equipment, from cameras and telescopes to GPS antennas and robotic arms.

Increased Efficiency: In applications like target tracking or navigation, where accuracy is critical, dual-axis gimbals contribute to faster, more reliable operation, reducing the time and effort required to achieve the desired results.

Ease of Integration: Modern dual-axis gimbals are designed to be easily integrated with existing systems, making them a flexible solution for various applications.

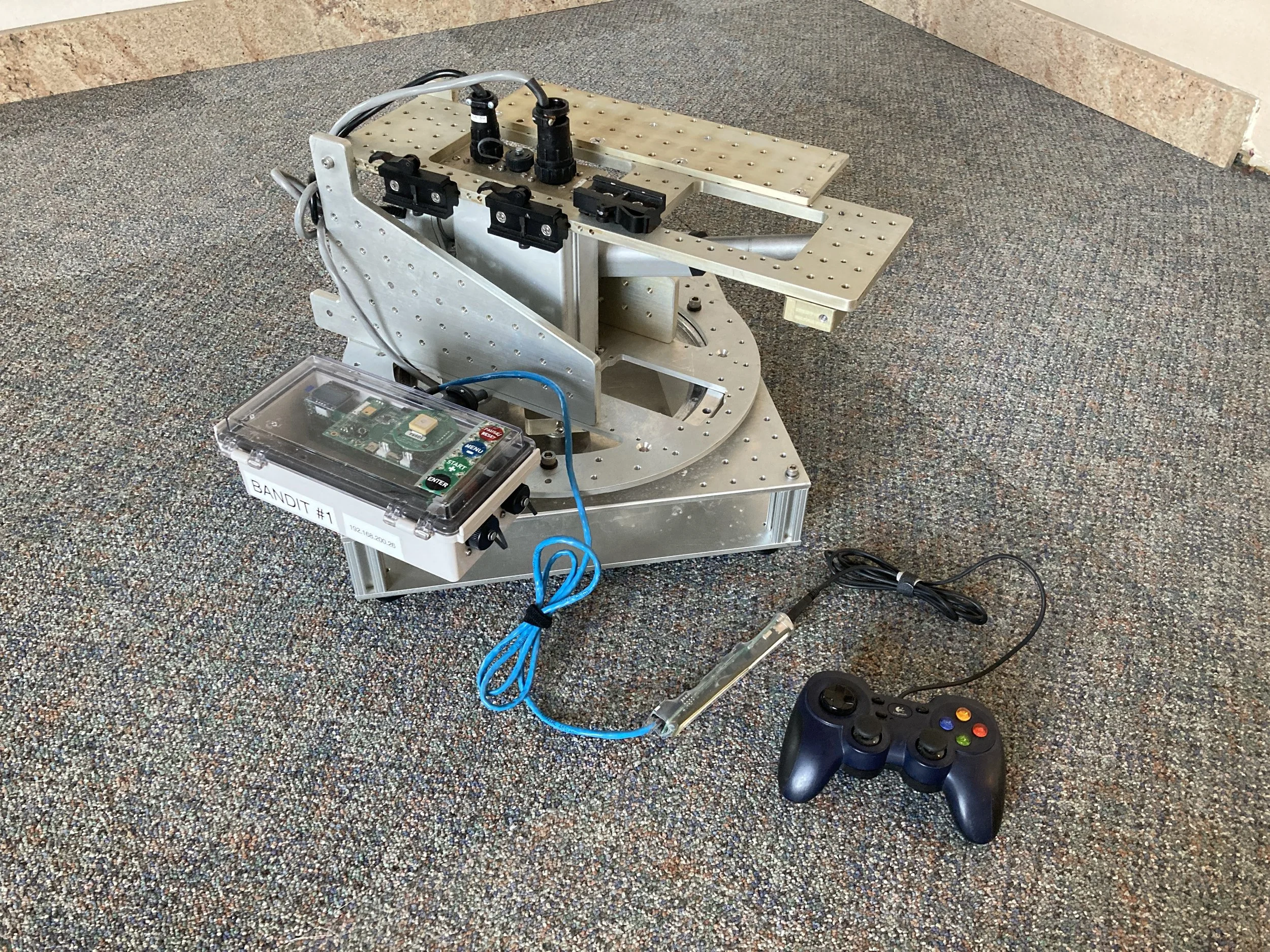

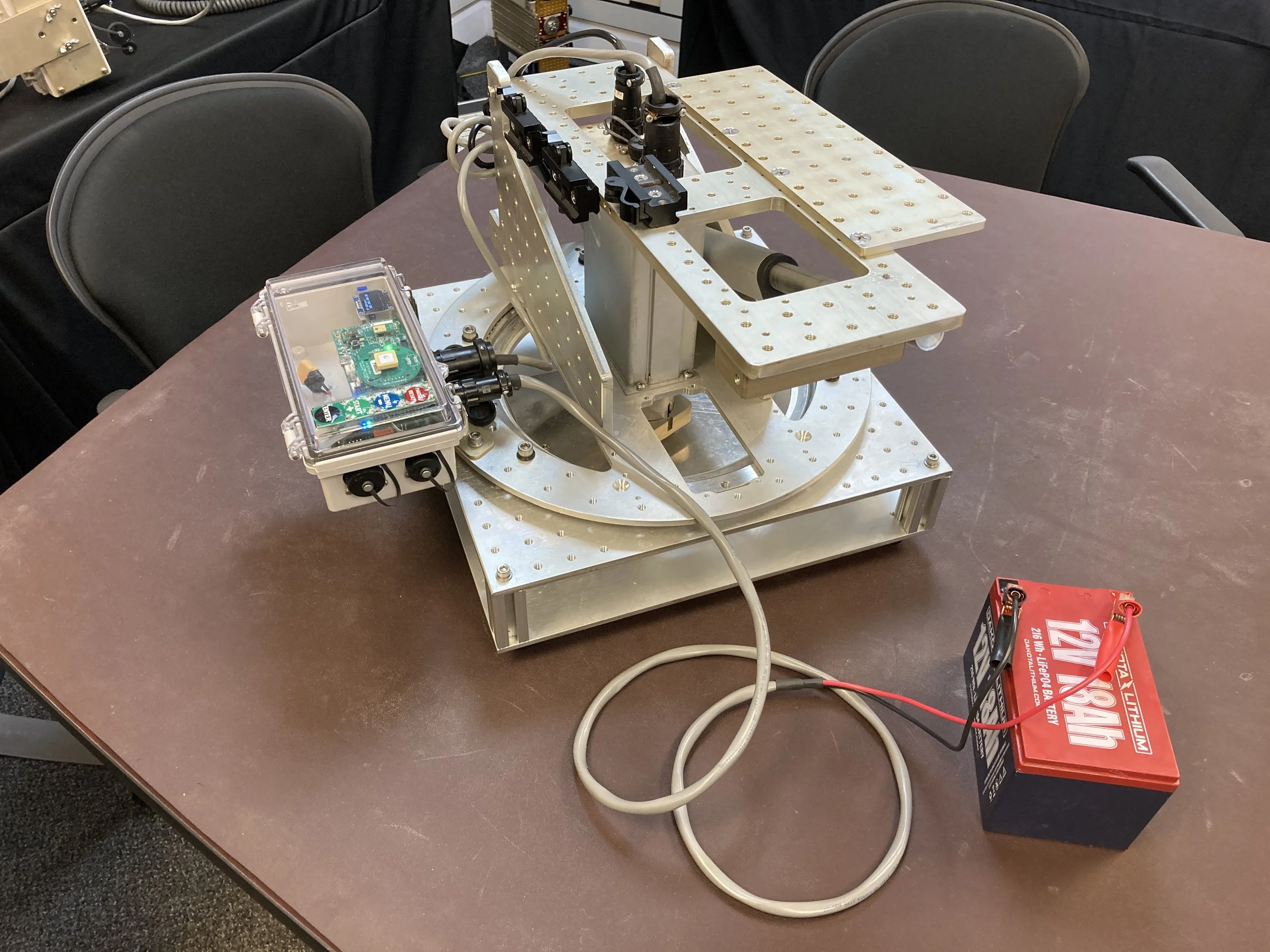

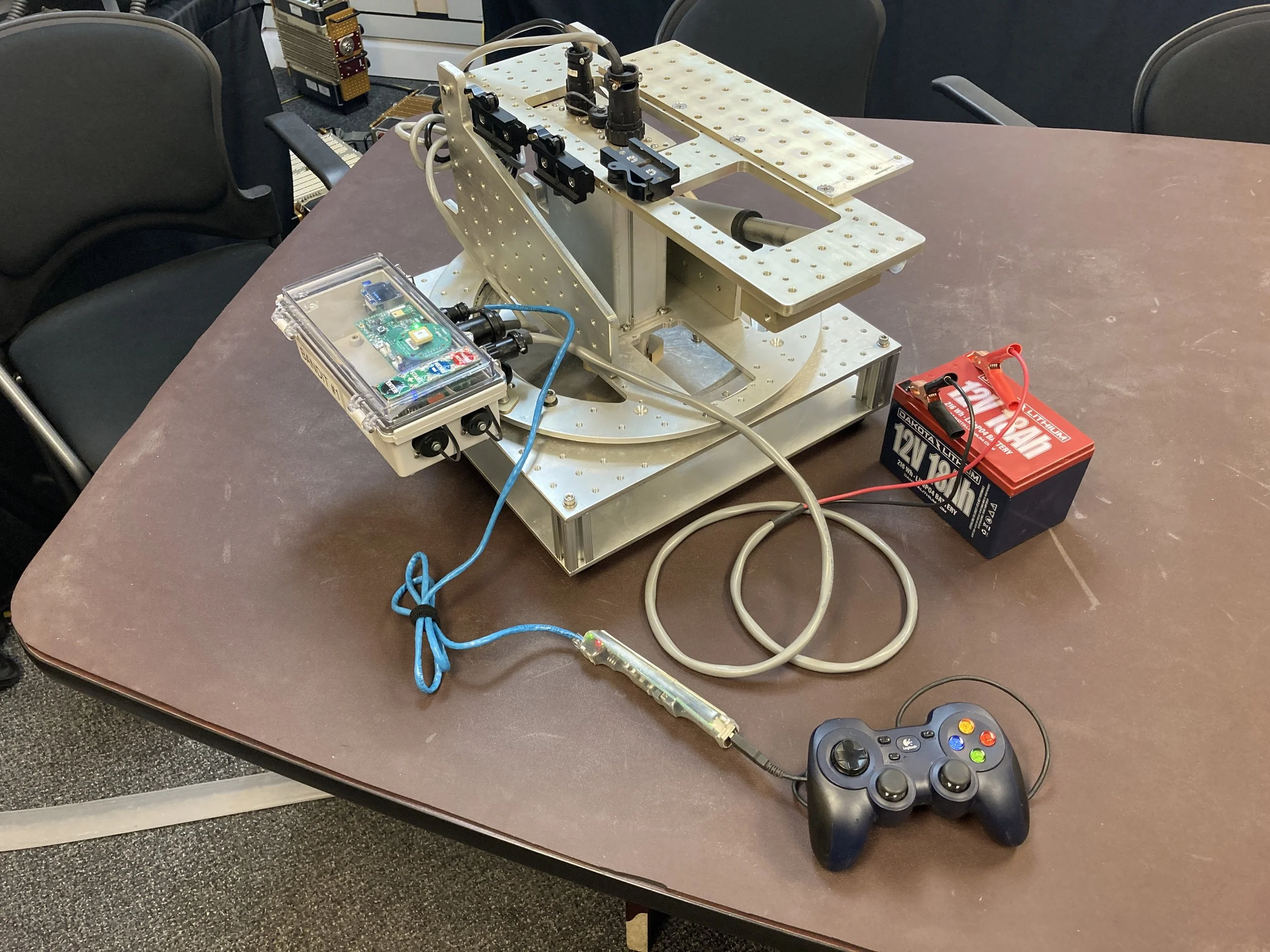

Lets Take a Look at the System

The Dual-Axis Gimbal for Remote Payload/Optics was designed using existing parts from the USV RIRAK kit. By developing an assembly kit that would use a pool of exiting parts, a USV kit could be consumed to become an effective platform for dual-axis motion to provide optics or even precision weapons package delivery. Using GPS capabilities from the USV kit, the Dual-Axis Gimbal platform can be set to monitor a precise GPS location for use in automated mobile surveillance or point defense applications.

Conclusion

Dual-axis gimbals are powerful tools that significantly enhance the performance of optics and positional tracking systems. By providing the stability and precision needed to maintain accurate orientation and tracking, these gimbals play a crucial role in a wide range of applications, from military surveillance to scientific research. As technology continues to evolve, the importance of reliable stabilization and control will only grow, making dual-axis gimbals an essential component in the pursuit of precision and accuracy.